MAXCRETE™ CEMENTING PRODUCTS

|

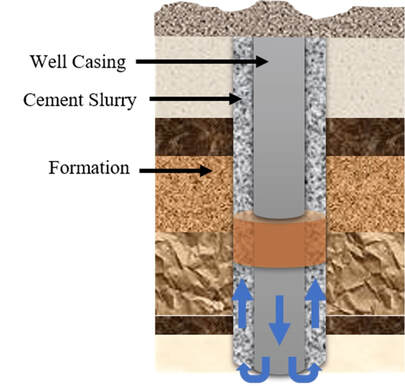

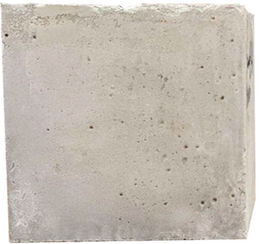

The MaxCrete™ line of cementing additives are designed to modify set time and flowability, vastly improving oil well cementing success. Our unique chemistry increases the degree of hydration of Portland cement thus changing the morphology of the set cement making it denser and less porous while greatly improving strength, reduced permeability and enhanced corrosion resistance.

It provides solutions for acceleration, retardation and extension of cement slurries. Approximately 15% of primary cementing jobs require remedial cementing. Maxflo’s chemists have worked with Portland cement for decades and have utilized this experience to provide innovative solutions for many of your cementing needs. MaxFlo also produces specialty additives that impact Portland cement at the molecular level.

<

>

|

MAXCRETE™ EVALUATION

-

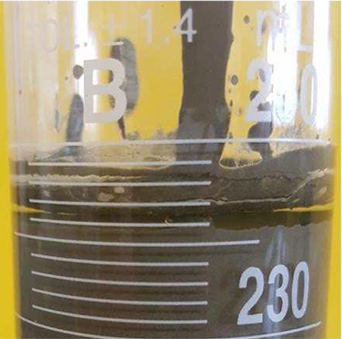

FREE WATER TEST

-

API FLUID LOSS FREE WATER RHEOLOGY

-

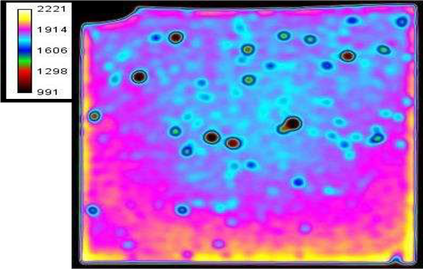

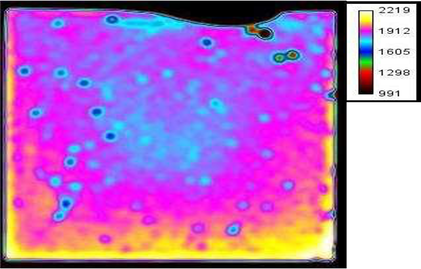

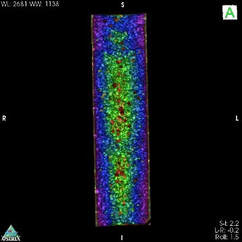

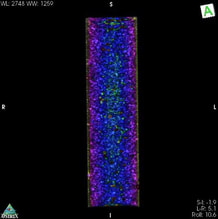

COMPUTED TOMOGRAPHY SCANNING

<

>

PROPERTY |

CLASS G CEMENT SLURRY |

CLASS G CEMENT + MAXCRETE™ 2.5 LB/100 LB CEMENT |

600 RPM |

148 |

132 |

300 RPM |

96 |

82 |

200 RPM |

77 |

66 |

100 RPM |

59 |

53 |

6 RPM |

22 |

18 |

3 RPM |

13 |

12 |

Yp, lb/100 ft2 |

44 |

32 |

Pv, cp |

52 |

50 |

GEL STRENGTH 10 sec |

21 |

17 |

FILTER LOSS, ml |

150 |

106 |

FREE WATER 90°, ml |

5 |

2 |